Steam Control

Steam is the most energy-efficient way to transfer heat for many food and beverage operations and it plays a part in many food processes. Mack’s valves ensure that potential risks of product contamination are avoided.

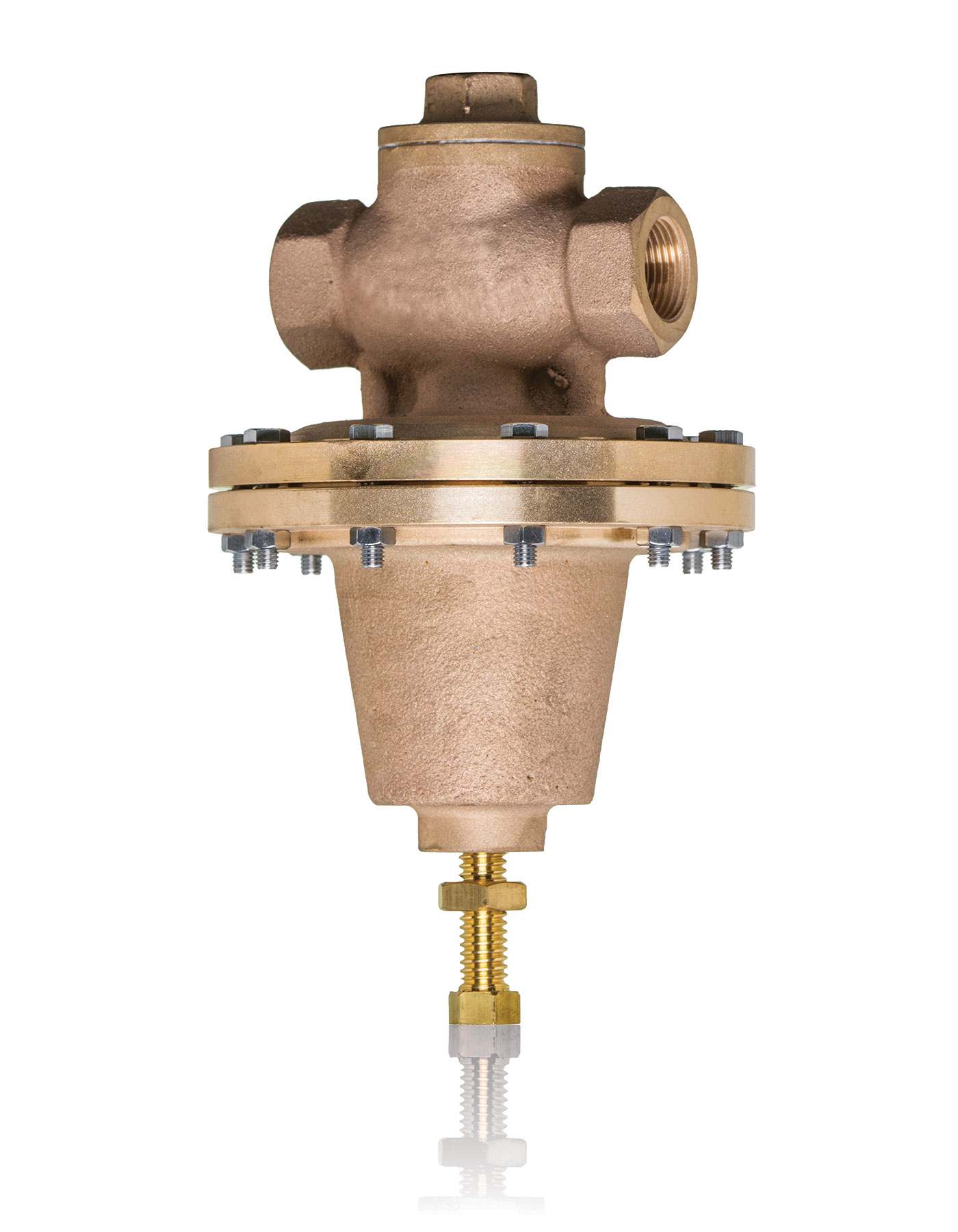

A precision steam

Trusted steam valves for food manufacturing

Mack Valves began in 1939 when Malcolm Edward Mack began procuring steam valves for the Navy. As a result of these pioneering efforts, several Australian Standards were developed around these products and their particular features recommended in many safety operational areas.

Steam remains a practical and environmentally sound way to convey heat energy. Automated steam valves regulate the steam pressure, temperature and flow to ensure reliability, delivery and efficiency for Australia’s manufacturing industries.

It is used to generate electricity, for food, chemical and other product processing, as a cleaning method, for heating and humidification.

Food processing factories, refineries, and chemical plants use steam to control the temperature in building heating, supply mechanical energy, remove contaminants and drive mechanical equipment.

Steam can clean a broad range of surfaces. High-temperature steam will sterilise food preparation equipment and remove contaminants from industrial equipment.

Mack Valves extensive range of valves for the Steam industry includes:

Download our datasheets for full product specifications

If your application requires a bespoke, custom-engineered solution, just ask us.

All build options are available from Mack on special order enabling clients to create a valve for their own specific needs, but our stock is based around common material specifications favoured by the Steam Control industry.

Speak directly to our specialist sales team to discuss your Steam valve needs, or to get a personalised quote, call +61 3 97375200